CAD-CAM (Computer-Aided Design and Computer-Aided Manufacturing) bridges represent a cutting-edge advancement in dental restoration technology. These bridges are designed and manufactured using sophisticated computer software and milling machines, providing a high level of precision, durability, and aesthetic appeal. CAD-CAM technology has revolutionized the way dental professionals create bridges, allowing for faster production times and highly customized solutions for patients.

Understanding Dental Bridges

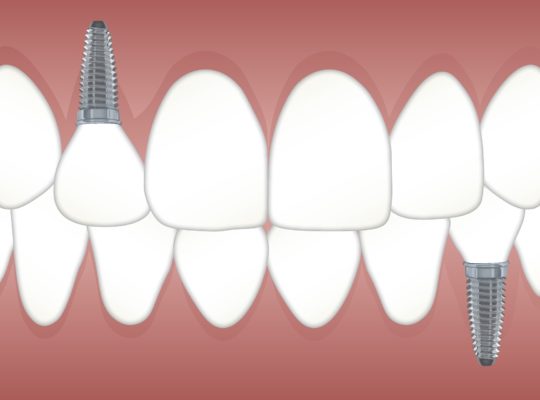

Before diving into CAD-CAM bridges, it’s essential to understand what a dental bridge is. A dental bridge is a prosthetic device used to replace one or more missing teeth. It is anchored onto adjacent natural teeth or dental implants and “bridges” the gap left by missing teeth. Traditional bridges require the preparation of the adjacent teeth to accommodate crowns that hold the prosthetic tooth (or teeth) in place.

Dental bridges are essential not only for restoring the appearance of a smile but also for maintaining the proper function of the mouth. They help in chewing, speaking, and preventing the remaining teeth from shifting out of position, which can lead to bite problems and other complications.

The Role of CAD-CAM Technology in Dentistry

CAD-CAM technology integrates digital design and manufacturing processes into dentistry. The system begins with a digital impression of the patient’s mouth, captured either through a digital scanner or by scanning a traditional mold. This digital model is then used to design the dental bridge with exacting precision, ensuring a perfect fit and natural appearance.

The key benefits of CAD-CAM technology in creating dental bridges include:

1. Precision and Accuracy:

CAD-CAM technology allows for the creation of highly precise dental restorations. The digital design process eliminates the possibility of human error, ensuring that the final product fits perfectly within the patient’s mouth.

2. Customization:

The digital nature of CAD-CAM allows for easy customization of the bridge. The design can be adjusted in real time, taking into account the patient’s specific dental anatomy, color, and aesthetic preferences.

3. Faster Turnaround Time:

Traditional bridges often require multiple dental visits and several weeks to complete. With CAD-CAM, the design and manufacturing processes are streamlined, reducing the time needed to produce the bridge. In some cases, it’s possible to design, fabricate, and place the bridge in a single dental visit.

4. Durability and Strength:

CAD-CAM bridges are typically made from high-quality materials like zirconia or porcelain, which are known for their strength and durability. These materials not only provide a long-lasting solution but also mimic the natural appearance of teeth, offering an aesthetically pleasing result.

The Process of Creating CAD-CAM Bridges

The process of creating a CAD-CAM bridge begins with the preparation of the patient’s mouth. If the bridge is to be anchored onto natural teeth, these teeth are prepared to receive crowns. If the bridge is to be supported by implants, the implants are placed and allowed to heal.

Once the mouth is prepared, a digital impression is taken. This impression captures the exact dimensions and contours of the patient’s teeth and gums. The digital data is then uploaded into CAD software, where the dentist or dental technician designs the bridge. This design process includes selecting the appropriate materials, shaping the prosthetic teeth, and ensuring the bridge will fit comfortably and function correctly.

After the design is finalized, the data is sent to a milling machine that carves the bridge from a block of the chosen material. The bridge is then polished, colored, and finished to match the patient’s natural teeth. Once complete, the dentist fits the bridge in the patient’s mouth, making any necessary adjustments to ensure comfort and function.

Advantages of CAD-CAM Bridges

CAD-CAM bridges offer several significant advantages over traditional bridges:

- Enhanced Aesthetics:

The precision of CAD-CAM technology allows for the creation of bridges that closely match the color, shape, and size of the patient’s natural teeth, resulting in a more natural-looking restoration.

- Improved Comfort:

The exact fit provided by CAD-CAM bridges ensures that the bridge feels natural in the mouth, improving overall comfort.

- Durability:

Materials like zirconia and porcelain are not only strong but also resistant to staining, making CAD-CAM bridges a long-lasting solution.

- Efficiency:

The reduced turnaround time for creating and fitting CAD-CAM bridges means less time in the dental chair and quicker results for patients.

Conclusion

CAD-CAM bridges represent the future of dental restoration, combining advanced technology with high-quality materials to create durable, aesthetically pleasing, and precisely fitting dental bridges. Whether you need to replace a single tooth or several, CAD-CAM bridges offer a reliable and efficient solution, restoring your smile and confidence with the latest in dental innovation.